Have you ever wondered how machines don’t lose any nuts or bolts despite all the vibrations, mechanical stress, and temperature fluctuations surrounding them? Well, major credit goes to the different threadlocker types that hold all the nuts, screws, and bolts together. Without the adhesive, thread fasteners can become prone to loosening, resulting in costly mechanical failure and safety hazards. SANVO houses a huge collection of various types of high-quality threadlockers that can give you the desired grip.

In this article, we’ll discuss everything about threadlockers and introduce you to their common types.

Threadlocker Types You Should Know

General Purpose Threadlocker

General-purpose threadlockers can be used for a wide range of applications, including repairing and assembling machinery. They are reliable when it comes to strength but also easy to remove when needed. This is why they are mostly used for applications that require frequent disassembling.

Medium Strength Threadlocker

Medium-strength threadlockers are higher-strength adhesives than general-purpose ones. This makes them most suitable for applications that involve vibrations more forceful than general-purpose threadlockers can handle. They may require a more forceful disassembly, but the process is still fairly easy and can be done with standard tools.

Premium Strength Threadlocker

A premium strength threadlocker is a high-strength threadlocker that can handle the most extreme vibrations and machine movement without resulting in loose fasteners. Though these threadlockers are often called permanent adhesives, this just means that they can’t be removed through standard tools. Instead, they are target-heated at high temperatures when the connected fasteners need to be disassembled.

Anaerobic Flange Threadlocker

Anaerobic flange threadlockers work best for applications that involve tight sealing flanges. They are not only resistant to vibrations but also formulated to prevent leaks and corrosion. The specialized formula of adhesive also guarantees an instant, low-pressure seal and adapts to the rough surface of flanges.

How do Threadlockers Work?

The working principle of threadlockers is based on anaerobic chemistry. Threadlockers are basically adhesives that remain in liquid or gel form when exposed to air. However, when the adhesive is applied between two threaded surfaces, e.g., nuts and bolts, to fasten them, the presence of metal ions encourages its curing reaction.

All threadlocker manufacturers recommend a specific curing time for different threadlocker types for effective results. That’s why it’s important not to subject the fasteners to any kind of load before the curing time is completed. Though threadlockers are powerful adhesives, they can be removed for disassembly if needed using tools and heat.

Applications of Threadlockers

Due to the prevalence of threaded fasteners in so many industries, the applications of threadlockers are countless. Following are some of the most popular ones:

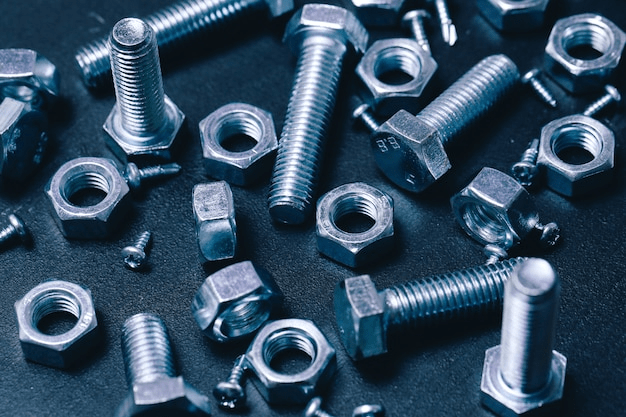

Nuts and bolts

Nuts and bolts are one of the most popular types of fasteners used even in the most basic industries. Be it automotive, construction, or manufacturing – all industrial machinery uses threadlockers to maintain smooth functioning and avoid accidents.

Metal fasteners

Apart from industries, different threadlocker types can also be useful for home repairs like loose screws in household appliances. Using a threadlocker for this issue can help prolong the life of the home appliance.

Motorcycle brake

In motorcycles, different threadlocker types are used for fasteners in components like brake calipers. Using the adhesive not only increases the life of the brake caliper but also protects riders from dangerous accidents caused by loosely fastened threads.

Wheel studs and lug nuts

12% of motor vehicle accidents are caused by mechanical failure, which includes loose screws. That’s why various threadlocker types are used on wheel studs and lug nuts in the automotive industry. They make sure that the fasteners are held in place to avoid wobbly wheels and potential accidents. They are especially handy in cars used for racing and off-road riding, where extreme vibrations are common.

SANVO’s Threadlockers

Depending on the level of adhesive strength, temperature, and vibration resistance required for your target application, Sanvo has a wide range of suitable threadlocker types. All our threadlockers, e.g., Anaerobic Flange Sealant SH-510, Premium Strength Threadlocker SH-271, etc., provide exceptionally strong and long-lasting adhesiveness compared to other options in the market. Apart from holding threads together, our threadlockers also have excellent sealing and anti-corrosion properties.

From high and medium-strength threadlockers to high-temp threadlocker options, we have an adhesive for every application. In addition, with the low manufacturing and maintenance cost of our products, you’re guaranteed to get a good bang for your buck.

Conclusion

A machine failure caused by loose thread fasteners can have catastrophic effects in terms of business reputation, repair costs, and workers’ safety. So, it’s vital to always go for a reliable threadlocker manufacturer.

At SANVO, we have a great number of satisfied clients from various industries. We are also well-known for our presales and after-sales services for import and export business.

Make sure to check out our threadlocker options at SANVO.